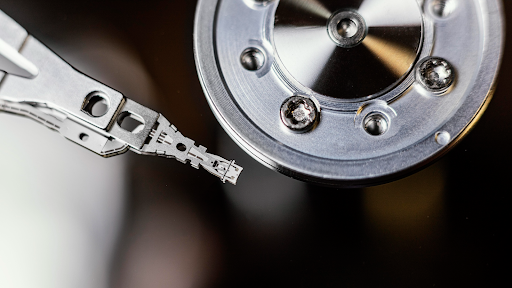

When it comes to maintaining the performance and safety of commercial vehicles, one of the critical components that require attention is the commercial vehicle axle bearing. Axle bearings play a vital role in enabling smooth wheel rotation and supporting the vehicle’s weight. Ensuring these bearings are in optimal condition is essential for efficient vehicle operation and to avoid costly downtime.

In this article, we will explore the common causes of axle bearing failure in commercial vehicles, helping fleet owners and operators understand the factors that can affect bearing life and how to mitigate these risks.

Understanding the Importance of Commercial Vehicle Axle Bearings

Before diving into the causes of failure, it’s important to recognize the function of the commercial vehicle axle bearing. Bearings reduce friction between the rotating axle and the stationary parts of the vehicle, facilitating smooth wheel movement and load distribution. Properly functioning axle bearings contribute to vehicle stability, fuel efficiency, and overall safety.

Given the demanding conditions commercial vehicles face, including heavy loads and long operating hours, axle bearings must withstand significant stress. Regular inspection and maintenance can help identify issues early, preventing more severe damage.

Common Causes of Axle Bearing Failure

1. Poor or Insufficient Lubrication

One of the primary reasons for axle bearing failure is inadequate lubrication. Bearings require consistent lubrication to minimize friction and heat build-up. If lubrication is insufficient or contaminated, it can cause the bearings to overheat and wear prematurely.

Lubricant contamination by dirt, water, or metal particles can accelerate wear. Therefore, using high-quality lubricants and following recommended lubrication schedules is crucial for the longevity of the commercial vehicle axle bearing.

2. Overloading the Vehicle

Commercial vehicles are often subjected to heavy loads, but exceeding the recommended load capacity puts undue stress on axle bearings. Overloading increases the pressure on bearings, causing excessive wear and early failure.

Fleet managers must ensure that vehicles operate within their specified load limits to maintain the integrity of axle bearings and avoid potential breakdowns.

3. Improper Installation

Incorrect installation of axle bearings can lead to misalignment and uneven load distribution. This causes excessive stress on certain parts of the bearing, leading to premature wear or failure.

Using genuine parts and following manufacturer guidelines during installation is essential. Professional installation by trained technicians helps ensure the commercial vehicle axle bearing performs as expected.

4. Exposure to Harsh Environmental Conditions

Commercial vehicles often operate in challenging environments such as dusty roads, muddy tracks, and wet conditions. These harsh elements can penetrate seals and contaminate bearings.

Water ingress and dirt contamination increase friction and corrosion risks. Regular inspection and timely replacement of damaged seals help protect axle bearings from environmental damage.

5. Excessive Heat

High operating temperatures caused by friction, overloading, or poor lubrication can degrade bearing components. Excessive heat reduces the strength of bearing materials and lubricants, accelerating wear.

Proper maintenance of braking systems and regular lubrication can control heat generation, preserving the life of the commercial vehicle axle bearing.

6. Impact Damage

Commercial vehicles may face impacts from potholes, road debris, or accidents. Such shocks can damage axle bearings by causing dents or cracks in the bearing surfaces.

Regular vehicle inspections can help detect impact damage early. Replacing damaged components promptly ensures safety and prevents further mechanical issues.

How to Prevent Axle Bearing Failure

Understanding the causes of failure enables commercial vehicle operators to take preventive measures:

- Regular Maintenance: Schedule routine checks for bearing condition, lubrication levels, and seal integrity.

- Use Quality Parts: Always choose genuine commercial vehicle axle bearing replacements like those offered by Tata Motors Durafit Parts.

- Adhere to Load Limits: Avoid overloading to reduce stress on axle bearings.

- Professional Installation: Ensure installation is performed by certified technicians using proper tools.

- Protect Against Contamination: Maintain seals and prevent water and dirt ingress.

- Monitor Operating Conditions: Pay attention to unusual noises, vibrations, or heat around the axle area.

Why Choose Tata Motors Durafit Parts for Commercial Vehicle Axle Bearings?

At Tata Motors Durafit Parts, we understand the rigorous demands of commercial vehicles. Our commercial vehicle axle bearing products are manufactured with precision, quality materials, and tested to meet high performance standards.

Choosing our parts ensures reliability, longer service life, and compatibility with your vehicle. Backed by Tata Motors’ legacy, our components support your fleet’s operational efficiency and safety.

Conclusion

Axle bearings are critical components that influence the performance and safety of commercial vehicles. Recognizing the common causes of axle bearing failure—such as poor lubrication, overloading, improper installation, environmental exposure, excessive heat, and impact damage—can help fleet operators take proactive measures.

For dependable and high-quality commercial vehicle axle bearing solutions, Tata Motors Durafit Parts is your trusted partner. Keep your commercial vehicles running smoothly by using genuine parts and adhering to regular maintenance schedules.

Ready to enhance your vehicle’s performance?

Explore the full range of Tata Motors Durafit Parts and ensure your commercial vehicles are equipped with the best.